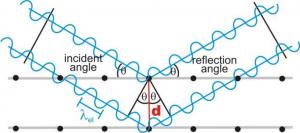

When a crystal with an interplanar spacing d (crystal lattice constant) is irradiated by X-ray beam with a comparable wavelength λ, the X-ray diffraction, or the constructive interference between elastically scattered X-ray beams can be observed at specific angles 2θ when the the Bragg’s Law is satisfied

When a crystal with an interplanar spacing d (crystal lattice constant) is irradiated by X-ray beam with a comparable wavelength λ, the X-ray diffraction, or the constructive interference between elastically scattered X-ray beams can be observed at specific angles 2θ when the the Bragg’s Law is satisfied

nλ = 2dsinθ

where n is any integer. In most diffractometers the X-ray wavelength λ is fixed and the diffraction angle θ is measured by goniometer, therefore the crystal lattice constants can be decided by above equation.

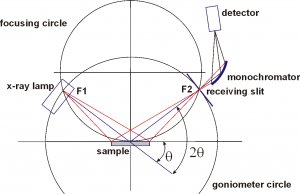

Bragg-Brentano (BB) Geometry

Most of powder diffractometers use Bragg-Brentano parafocusing geometry, offering high-resolution and high beam-intensity analysis at the cost of very precise alignment requirements and carefully prepared samples.

Most of powder diffractometers use Bragg-Brentano parafocusing geometry, offering high-resolution and high beam-intensity analysis at the cost of very precise alignment requirements and carefully prepared samples.

- The incident angle ω between X-ray source and the sample is always 1/2 of the detector angle 2θ: 1) ω:2θ or θ:2θ scan: with the X-ray tube fixed, the sample rotates at θ/min and the detector always at 2θ/min; and 2) θ:θ scan: the sample is fixed and the tube rotates at the same rate as the detector at θ/min.

- Sample surface is kept on the tangent plane of the focusing circle defined by three spots at sample, X-ray source and receiving slit.

- The incident- and diffracted-beam slits move on a circle that is centered on the sample. Divergent X rays from the source hit the sample at different points on its surface. During the diffraction process the X rays are refocused at the detector slit.

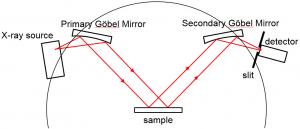

Parallel-Beam (PB) Geometry

The PB optics provides accurate measurement of diffracted X-ray positions unaffected by sample shape. It is generally used to analyze powder sample profiles, the degree of preferred orientation and thin films.

The PB optics provides accurate measurement of diffracted X-ray positions unaffected by sample shape. It is generally used to analyze powder sample profiles, the degree of preferred orientation and thin films.

- A polycapillary collimating optic (Göbel Mirror) is used to form an intense parallel X-ray excitation beam resulting in very high X-ray intensities at the sample surface.

- No restrictions on XRD configuration from BB geometry which allows broader range of sample shapes and sizes.